PUMA 4100 series machine tools are used in automotive rear axle housing production lines

The PUMA 4100 series machine tool is a horizontal turning center specifically designed for machining medium and large workpieces. This series of machine tools is a high-power cutting machine tool using a two-stage gearbox and a high-torque motor, featuring a high-rigidity hard rail structure. By using the optional Y-axis function and the optional Dean machine tool threading function, complex workpieces can be machined, making it an ideal solution for many industries and applications. Beijing Smart technology Co., ltd. applies this model to the automotive rear axle housing machining production line. Large and complex parts can be machined with a single clamping, and currently, the production line operates stably, creating value for customers.

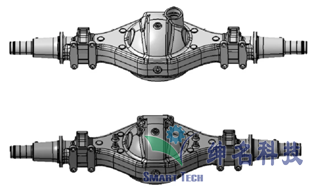

The rear axle housing is a crucial component of a vehicle; it constitutes the drive axle together with the main reducer, differential, and wheel drive mechanism. The axle housing not only supports the vehicle's weight and transmits the load to the wheels but also withstands the reaction forces and moments of the traction force, braking force, lateral force, and vertical force transmitted from the drive wheels, transferring them to the frame or body through the suspension. If the axle housing is affected by impact loads generated between the wheels and the ground, it may cause deformation or fracture. Therefore, the drive axle housing needs to have sufficient strength, stiffness, and good dynamic characteristics. Rational design and manufacturing of the drive axle housing is an essential measure to improve vehicle driving stability.

The PUMA 4100 series machine tool boasts strong machining capabilities, thanks to its two-speed gearbox, high-torque main spindle motor, and stable hard rail structure, optimizing cutting performance. The gearbox is designed to provide the PUMA 4100 spindle with high power and high torque, thereby improving productivity and process reliability in heavy-duty machining operations.

The PUMA 4100 series machine tool has a turning diameter of Ø650 mm and a turning length of 3m. Its spindle speed can reach 1500 r/min, and the spindle power (30min/continuous) can reach 45/37kW, with a spindle torque of 4038 N•m. Turning centers with chuck sizes ranging from 12 inches to 21 inches are available, with options for large-diameter spindles, 1m/2m/3m turning lengths, and 2-axis to Y-axis configurations. The turret is standard with 12 tool positions; a 10-tool position is optional for increased turret rigidity. Turret rotation is servo-motor controlled to ensure fast and reliable tool selection. The unique BMT85P turret design is used on M and Y models to enhance the heavy-duty milling performance of these machines. In addition, the newly designed control panel and optional threading function also increase efficiency.