PUMAV405 & VC4305 series products are used in brake disc machining

Brake rotors are crucial components in a vehicle's braking system. Their function is to reduce vehicle speed or bring it to a stop by using the brake caliper to clamp the rotor, generating friction when the vehicle is traveling at high speed. Beijing Smart technology Co.,ltd. applies its PUMAV405 & VC4305 series products to brake rotor machining, helping customers save costs while improving efficiency.

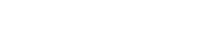

Common machining processes for brake rotors are as follows:

The PUMA V405 vertical turning center adds a servo dual-sided tool post to the standard equipment, facilitating simultaneous machining of the two braking surfaces on the brake rotor and ensuring their parallelism.

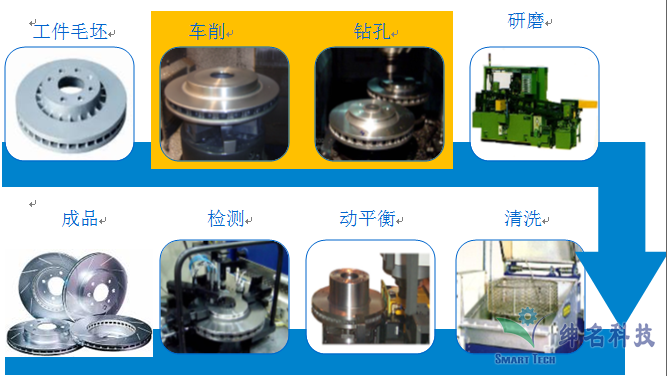

The VC4305 vertical dual-station machining center is designed for high speed and high productivity while maintaining long-term operational accuracy. Its 15kW high-torque spindle motor and dual-belt drive, along with a high-speed automatic tool changer (the clamping function of the tool changer ensures high precision), guarantee product accuracy while reducing workpiece loading and unloading time. Process and clamping diagram:

Contact Us

Address: Room Wangjing SOHOT2-1-1606, No.1 Futong East Street, Chaoyang District, Beijing (100102)

Telephone:010-57076158

Fax: 010-57076358

Website:www.beijingsmart.com

E-mail:master@beijingsmart.com

Video Number

Subscription Number

TikTok

Small program