Dean Machine Tools (formerly "Doosan Machine Tools") NHM series horizontal machining center for high-efficiency machining of difficult-to-cut materials

The engine block is one of the parts in an automobile product. The machining quality and production efficiency of the automobile engine block to some extent affect the production efficiency and performance of the automobile. In the face of problems such as how to achieve high-productivity machining of difficult-to-machine material workpieces, the Dean machine tool (formerly "Doosan machine tool") NHM series high-performance horizontal machining center provided by Beijing Smart Technology Co., Ltd. offers a wider range of processing specifications and production capacity (including powerful cutting capabilities) than comparable equipment, meeting the various needs of customer production.

The all-hardened, integral bed structure, with its high rigidity required for high-power cutting processes, enables productive machining of workpieces ranging from general workpieces to those made of difficult-to-machine materials. In addition, the servo motor-driven tool changing structure and worktable exchange device reduce non-cutting time, achieving the reliability and productivity of the NHM series equipment.

▶ Servo-driven ATC (Automatic Tool Changer)

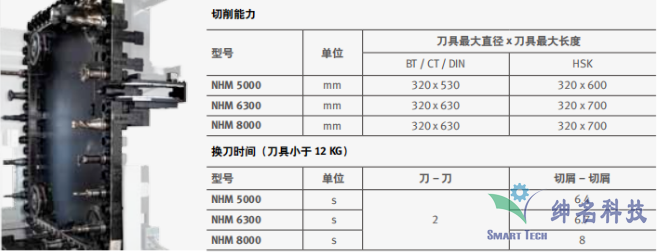

With its servo motor and rapid tool indexing and spindle positioning functions, this ATC (Automatic Tool Changer) can handle tools weighing 25-30 kg during high-speed operation.

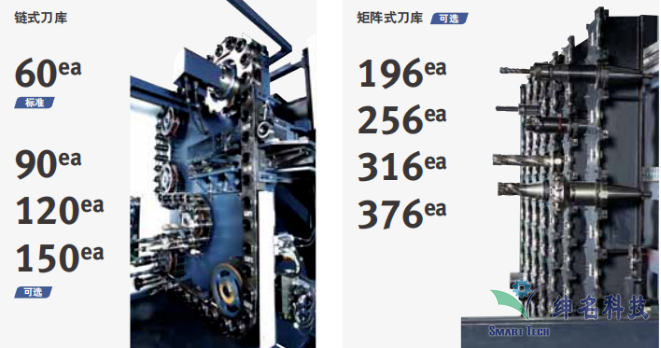

▶ The tool magazine can store various tools, including chain-type and matrix-type tools.

The NHM series comes standard with 60 tools and an optional 376 tools.