Hybrid processing addresses new manufacturing trends and meets diverse customer needs

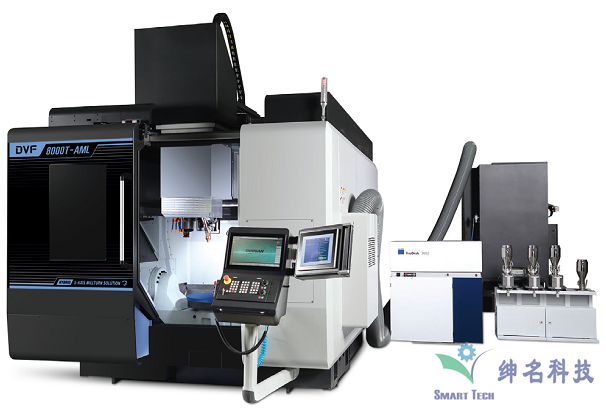

01. Deposition Machining and Cutting Machining

Not opposing camps

Depending on the characteristics of the shape and material, cutting and deposition have different advantages and disadvantages. Lee Gangjae, director of the Advanced Technology Group at Doosan Machine Tools (formerly "Doosan Machine Tools") R&D headquarters, emphasized that these advantages and disadvantages are complementary, not competitive structures.

If deposition machining is used to create shapes in areas requiring only high-priced materials for special functions, not only can processing time be shortened, but the amount of discarded material can also be significantly reduced, thereby lowering the overall cost.

02. For shape creation, repair, and functional strengthening

Cutting/Deposition Hybrid Process

In current metal processing, the increasingly popular deposition hybrid market can be divided into three main parts: "shape creation," the process of creating shapes; "repair," processing after repairing damaged parts of specific shapes; and "functional strengthening," depositing high-priced materials onto workpieces machined from general materials to give them special functions such as corrosion resistance and heat resistance.

Lee Gangjae, director of the Advanced Technology Group at Doosan Machine Tools (formerly "Doosan Machine Tools") R&D headquarters, also stated, "Especially in cases where molds for automotive and electronic parts and high-priced parts for energy/defense are damaged, deposition machining is frequently used for repair."

03. Doosan Machine Tools (formerly "Doosan Machine Tools"), starting 8 years ago

Preparing for the expanding demand for deposition machining

Doosan Machine Tools (formerly "Doosan Machine Tools") began focusing on deposition machining solutions, with equipment integrating deposition machining functionality onto 5-axis machining centers first unveiled at EMO 2013. It also participated in the "Large-Scale Deposition Machining Infrastructure Construction Project" held by the Korea Automotive Research Institute's Advanced Automotive Research Center in 2019, achieving significant results in this field.

04. Doosan Machine Tools (formerly "Doosan Machine Tools")

Possesses a lineup of deposition machining products

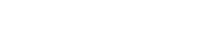

At Doosan Machine Tools (formerly "Doosan Machine Tools") DIMF 2021 virtual exhibition, the 'DVF' vertical machining center with metal deposition functionality was unveiled. The DVF Model, a deposition/cutting hybrid equipment based on a high-precision synchronous 5-axis machine tool, is divided into DVF 5000-AML/8000-AML/8000T-AML Models; the model installed in Lingyan is the "DVF 8000T-AML." Doosan Machine Tools (formerly "Doosan Machine Tools") plans to break into the hybrid machining market with its widely applicable "DVF series" as the vanguard; the "VCF 850 LSR" Model, suitable for large workpieces, is also about to be unveiled. Simultaneously, operator manuals on power selection methods and deposition processes are being prepared, and highly advanced solutions for deposition monitoring technology are also being promoted.

To proactively respond to the new trends in production and manufacturing in the era of great integration, Doosan Machine Tools (formerly "Doosan Machine Tools") continuously professionalizes its Customer Service, including solutions for "smart equipment," "smart manufacturing," and "smart factories." At the same time, to help customers expand their business areas and solve difficult technical problems, it has developed new solutions and product lineups in the field of deposition machining. In the future, in the field of metal processing, it will develop more solutions and product lineups to become a "metal processing platform" company that leads changes in production and manufacturing trends.