Dean Machine Tools (formerly Doosan Machine Tools) mold technology, providing customers with high-quality solutions

Dean Machine Tools (formerly "Doosan Machine Tools") uses DSQ, DAFC, and DHC in its mold technology to provide high-quality solutions.

Extensive experience and expertise

For decades of deep cultivation in the mold market, we have been continuously improving and updating our accumulated experience and expertise.

Various mold solutions

Mold solutions applicable to various molds (e.g., stamping/plastic/forging/die casting molds).

Customer First

We always adhere to the customer-first philosophy, providing customers with solutions to achieve the expected results under various conditions.

Comprehensive Full-Process Management

We will continuously consider customer needs, providing full-process services from pre-purchase qualification to on-time delivery, as well as comprehensive after-sales service for mold solutions.

Molds can be divided into different types. According to the Applications and materials of the molded products, they can be divided into plastic molds, stamping molds, die-casting molds, forging molds, and other special molds.

Plastic

Hose connector

DVM 500Ⅱ High-speed, high-precision vertical machining center

Options:

1 Tool length measurement: TS27R

2 Mold package: DSQ3 (data server 1GB, pre-read 600 program segments)

Machining process: Fine machining with D3 ball-nose end mill

1 Feed rate 1200mm/min

2 Spindle speed 15000r/min

3 Machining time 17 hours

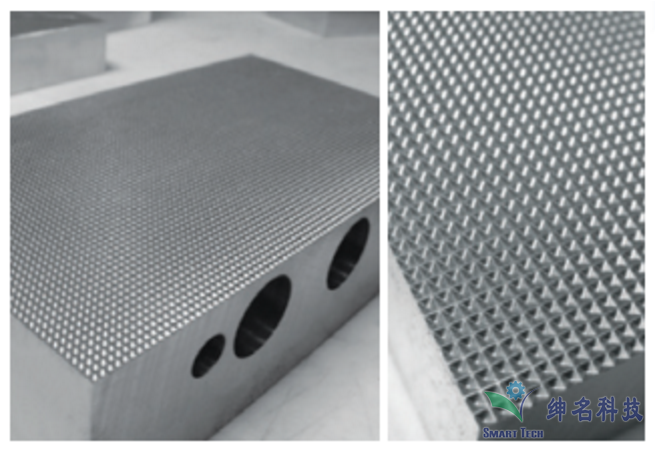

Embossed pattern

FM 400 Ultra-high-speed, ultra-high-precision vertical machining center

Options

1 Tool length measurement: TS27R

2 Mold package: DSQ3 (data server 1GB, pre-read 600 program segments)

3 Provide special lubrication to the Z-axis: Repeated Z-axis movement of short stroke

Machining process: D0.8 Ball Endmill

1 Feed rate 600mm/min

2 Spindle speed 32000r/min

3 Machining time 49 hours

Automotive mold

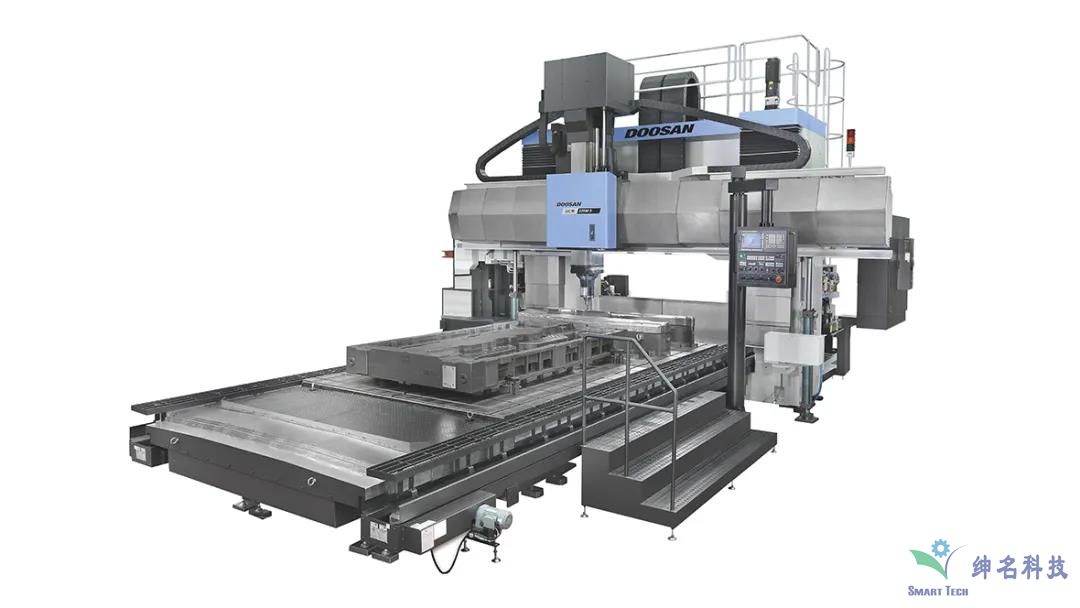

DCM 2740F Ⅱ High-precision gantry machining center