Dean Machine Tools (formerly Doosan Machine Tools) Aerospace Solutions

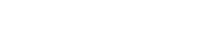

01 Structural Components

The BM series is suitable for airframe skeleton manufacturing

Equipment Features: The BM general-purpose series is a gantry machining center suitable for processing ordinary parts. Using a new equipment structure to improve customer productivity and create greater added value.

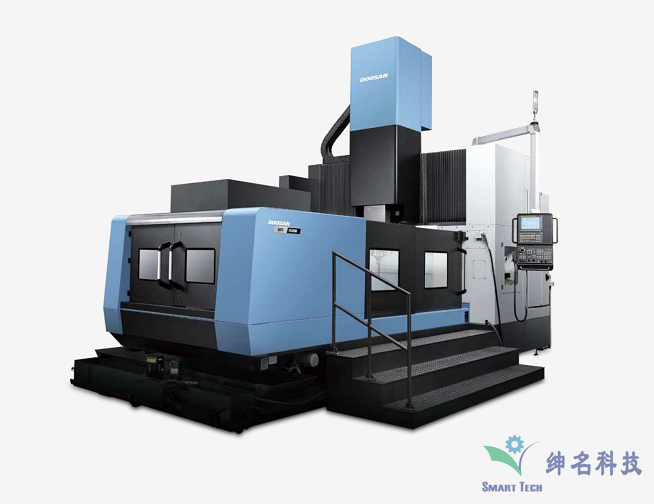

The DBC series is suitable for tail pylon manufacturing

Equipment Features: Using advanced technology, this vertical column-moving CNC boring and milling machine can produce a variety of parts from medium to large size, including molds and mold accessories. Through technological improvements, we have enhanced operational convenience and efficiency, creating greater value for our customers.

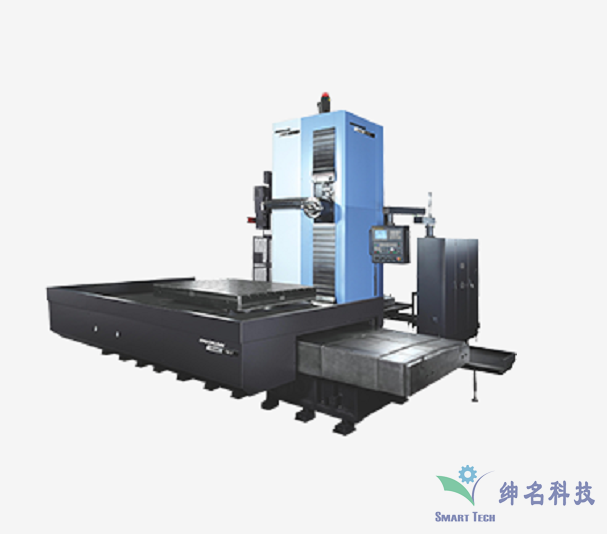

The PUMA SMX series is suitable for main rotor manufacturing

Equipment Features: The PUMA SMX series combines high productivity, high-precision processing capabilities, and ease of operation into one compound turning center. This series integrates the processing functions of multiple ordinary equipment, minimizing operating time and labor costs, and its processing performance far surpasses similar products.

02 Landing Gear Components

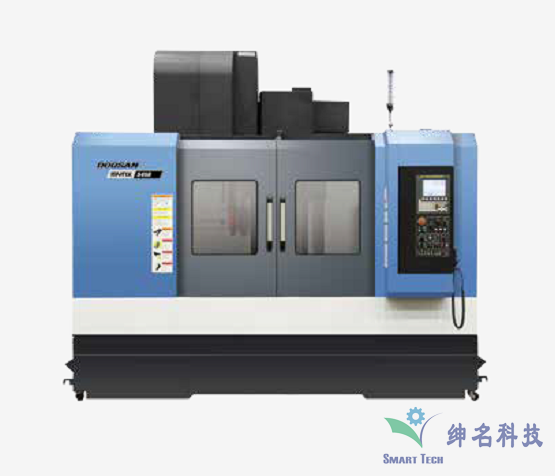

The VM series is suitable for hanger manufacturing

Equipment Features: The VM series is a vertical machining center suitable for mold processing. Equipped with the largest stroke and low-vibration main spindle in its class, it can achieve both rough and fine machining. The designed equipment structure provides value to customers in terms of ease of use and high productivity.

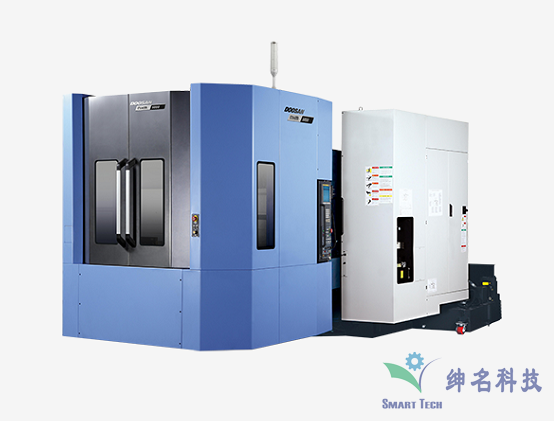

The NHM series is suitable for bracket manufacturing

Equipment Features: The NHM series, with its hard rail integrated bed structure and the rigidity required for cutting processes, can process general workpieces to difficult-to-cut material workpieces. In addition, the servo motor-driven tool changing structure and the worktable exchange device significantly reduce non-cutting time, achieving high reliability and productivity for the NHM series equipment.

The PUMA V series is suitable for brake disc manufacturing

Equipment Features: The PUMA V series is designed for long-term precision maintenance and heavy-duty turning, with a small footprint. The high-power spindle drive structure, close-fitting cast iron, and integral box-type guide rails provide good rigidity.

03 Engine Components

The PUMA VTR series is suitable for engine manufacturing

Equipment Features: The PUMA VTR series, a sliding-headstock vertical turning center, has the largest table diameter (Ø1600/2000mm) among similar products. Using a rigid wide-column structure further expands the processing range and improves stability.

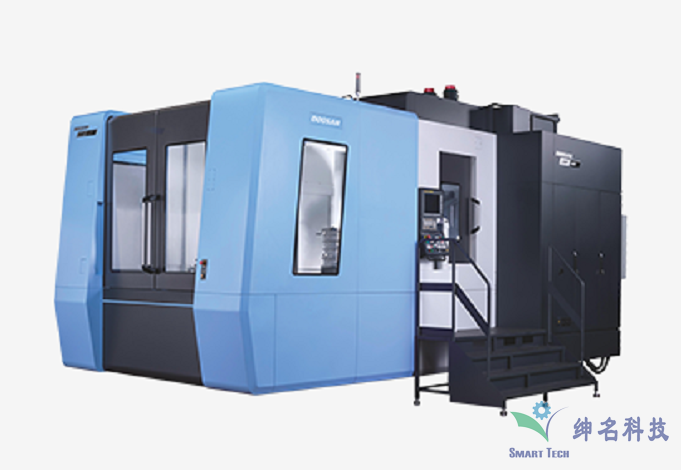

The DHF series is suitable for integral impeller manufacturing

Equipment Features: The DHF series is a five-axis linkage horizontal machining center equipped with an A-axis swing-type spindle. It has a rigid structure, and the X and Y axes use double ball screws. It can meet different processing needs of customers, from machining hard materials such as titanium and chrome-nickel alloys to high-speed machining of aluminum materials.

The VC630/5AX is suitable for blade manufacturing

Equipment Features: The VC630/5AX five-axis linkage vertical machining center is equipped with a rigid rotary table and a five-axis linkage machining center, mainly providing efficient processing for complex multi-contour workpieces.