Dean Machine Tools (formerly "Doosan Machine Tools") in the application of oil equipment parts processing - valve body parts processing

Machining of valve body parts

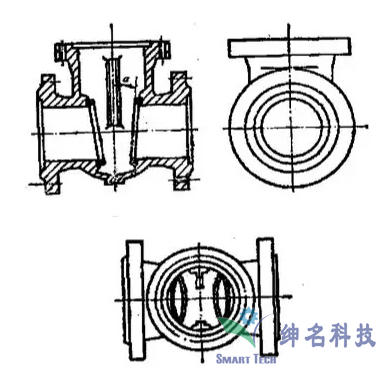

Flanged straight-through three-way valve bodies are a common structural form of gate valves, globe valves, check valves, pressure reducing valves, and throttle valves. This type of valve body is widely used and has a large market share.

Gate valve bodies are hollow, thin-walled shell parts, mostly three-way tubular, used in straight pipelines. The inlet and outlet passages of the valve body are coaxial, hence the name straight-through type (see figure below).

Most of the main machined surfaces of the valve body are rotating surfaces. Therefore, except for the guide rib parts which are machined on a milling or planing machine, the remaining surfaces are machined by turning. Because the sealing surface requires high precision and surface finish, and the machining allowance of the casting blank is large, the gate valve body can be divided into two stages: rough machining and finish machining. During rough machining, the three flanges are machined first, and then, with the flange as the reference, the sealing surface is precision turned using an angled oblique tool. After precision turning, the sealing surface still does not meet the geometric shape accuracy and surface finish requirements of the drawing, and must undergo finishing machining - grinding.

Doosan Machine Tools (formerly "Doosan Machine Tools")Application of HM805 horizontal machining center in valve body machining:

Tianjin B Group Company isBeijing Smart technology Co.,ltd.a customer. To adapt to the development of the times, improve production efficiency, and improve product quality, it has introducedDoosan Machine Tools (formerly "Doosan Machine Tools")the HM805 horizontal machining center to machine valve bodies and other key components, replacing the traditional coordinate boring machine. The company usesDoosan Machine Tools (formerly "Doosan Machine Tools")the HM805 horizontal machining center. After machining, the processing of a single product has changed from multiple processes and multiple workstations to a single process and a single workstation, greatly reducing the manpower and time wasted due to the turnover between processes and workstations, and the production efficiency has increased several times. The machining accuracy of the workpiece is good, and the product assembly performance is improved.

(Note:Beijing Smart technology Co.,ltd.,Since the 1990s, it has been engaged in the sales and service of Doosan Machine Tools (formerly "Doosan Machine Tools"). In 2008, the annual sales volume of machine tools exceeded 200 units, and in 2010, it exceeded 400 units. As of 2015, the cumulative total sales of Doosan Machine Tools (formerly "Doosan Machine Tools") by Shenming Technology has exceeded 7000 units.)

The introduced Doosan Machine Tools HM805 is a full-hard rail, high-rigidity horizontal machining center specially designed for Chinese customers - the high-rigidity box-type guide rail can achieve high torque, improving the overall heavy cutting capacity of the equipment, mainly used in heavy cutting machining of petroleum equipment parts.

HM805 model features:

- The ATC structure adopts the company's own ATC structure, reducing vibration and more effectively preventing tool drop during tool exchange.

- On the APC structure, bearings are added between the center axis of the worktable and the piston, improving the durability during the exchange process.