XC 4000-2SP Series

Key words:

XC 4000-2SP Series

Classification:

Dual spindle machining center

XC 4000-2SP Series

High productivity dual-spindle column moving vertical machining center

The XC 4000-2SP dual-spindle vertical machining center is designed to meet the demands of high-volume part production. With two 12000r/min direct drive spindles, it ensures high-speed machining and increases productivity. By using a mineral casting bed, it maintains machining stability and accuracy during long-term production. It is suitable for automated part loading systems, achieving unmanned automation.

Excellent Machining Capability

Excellent processing capability

High Precision

High precision

Faster Machining

High-speed machining

Highlights

Optimize the bed structure,

achieve high precision and high productivity in processing.

To optimize durability and rigidity, a dual ball screw structure has been adopted.

High rigidity · High precision

Chip to chip: 3.8 seconds) The automatic door is optimized for high-speed tool change (linear guide rail and cylinder drive)

Meet various processing needs of customers

It is also suitable for automation using robots or trusses.

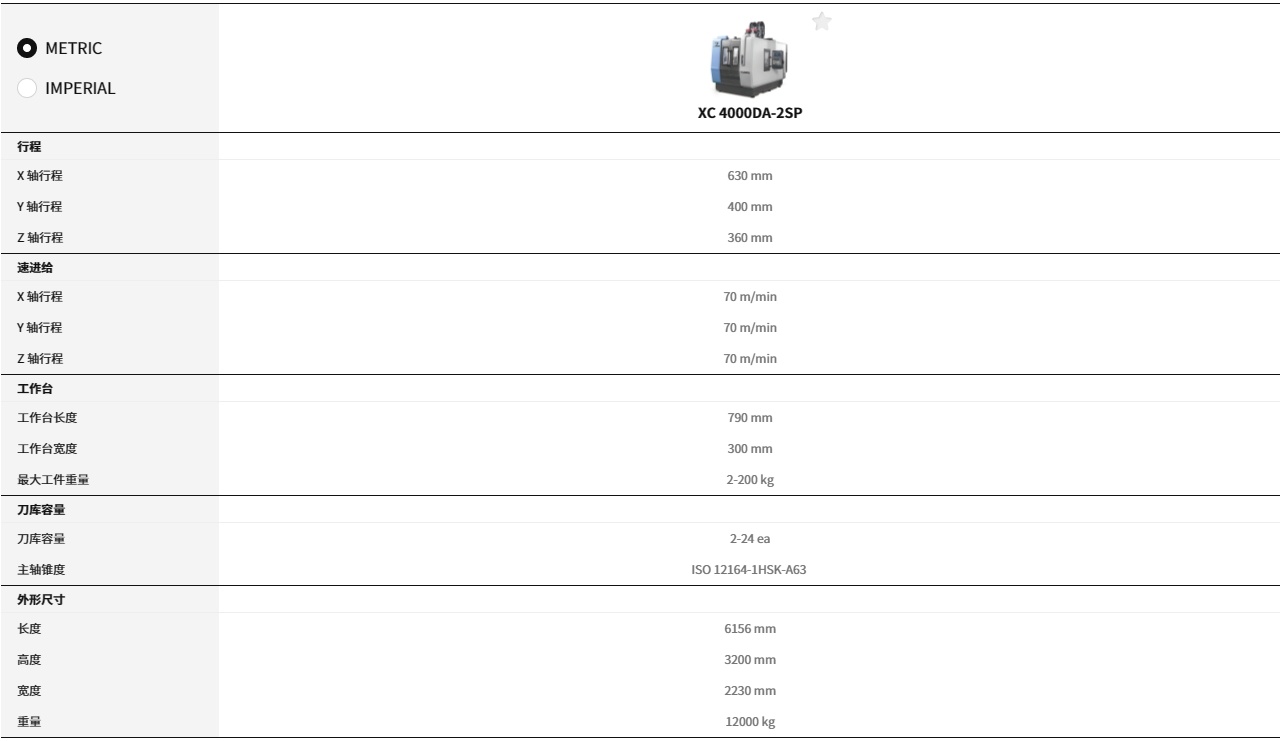

Product Specification

This product specification complies with global standards and may vary slightly from region to region.

Related Products

Welcome your message consultation